A Montana, USA, company claims to have found a low-cost, environmentally safe solution to power electric vehicles for generations to come, thanks to a technology developed by Lawrence Livermore National Laboratory (LLNL). The Kalispell, Montana-based Zinc Air, Inc. (ZAI) announced recently that it had obtained exclusive rights from LLNL for the zinc air fuel cell (U.S. Patent 5,434,020) invented by John Cooper, a retired LLNL chemist.

According to ZAI co-founder and president Dave Wilkins, there is enough readily available zinc just to produce billions of these batteries. Worldwide resources of zinc total more than 1.8 gigatons—with more than 35 percent of that in the United States alone.

Zinc Air Battery

Global zinc production in 21 months would be sufficient to produce one billion 10 kWh zinc air batteries—by contrast it would take 180 years of lithium production to produce those same batteries as lithium-ion units. These figures were quoted in a recent white paper by Meridian International Research, which stated, “Lithium supply and future production will be far from adequate to sustain global electric vehicle production.”

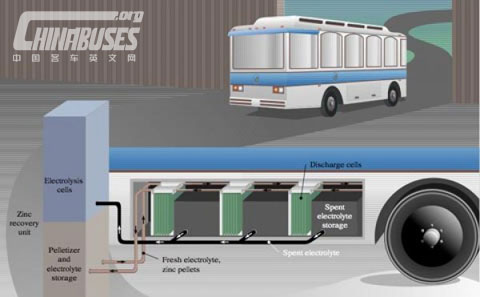

In the short-term, this new technology has the potential to positively impact fleets of electric vehicles, that combine high daily usage, low-power requirements, and an in-place service infrastructure, according to the manufacturer. There is an enormous market for lightweight, low-power, zero-emission vehicles like buses that can operate multiple shifts. Rapid refuelling of zinc air batteries—as opposed to overnight recharging—makes multiple shifts a reality. With 10-minute refueling, this technology allows battery use up to 24 hours a day.

“The contrast with lithium batteries in terms of environmental consequences must not be overlooked,” said Wilkins. “The byproduct –zinc oxide—is 100 percent recyclable.” The technology enables safe, lower-cost, clean, quiet, reliable and environmentally friendly power generation. Zinc Air Fuel Cell (ZAFC) products combine atmospheric oxygen from the air we breathe with zinc metal pellets as the fuel to generate electricity. In operation, the fuel cell consumes all of the zinc and is operationally quiet, providing instantaneous electrical energy with no greenhouse gas emissions. It also doesn’t contain any of the toxic elements found in lithium batteries or other battery chemistries.

Zinc Air technology is now seeing life because of the anticipated demand for efficient, low-cost alternatives to lithium for electric vehicle battery production. One of the many benefits of this technology is that it enables continuous fuel feed while the system is under load, making it ideal for electronic vehicle and fleet power supply.

ZAI is in discussions with multiple fleet vehicle manufacturers to develop products for their immediate needs. The company intends to begin development and testing in late 2010 with full-scale field testing in the second quarter of 2011.