A re-interpretation of the breed and more than a bit of Aussie bus-industry know-how has seen Chinese-based but Australian-imbued bus builder Bonluck produce the latest classy version of its popular President product.

PRESIDENT ELECT

Could this be a story about a quiet little bus that stood all by its lonesome in some dark and dingy corner of a major commercial vehicle show hoping it might get seen? No. No, it’s not! This is a story of a brand-spanking-new Bonluck (BLK) President 2 ‘1600’ coach - resplendent in a gorgeous bright Hyundai green - virtually plonked smack bang in the middle of a hall basking in its own limelight and subliminally shouting out ‘Look at me, Kimmy! Look at me!’ to hundreds of passers-by at the Melbourne 2015 BusVic Maintenance Conference and Expo. And you know what? That’s just what they did. And so did we.

Indeed, it was hard to ignore the modern and classy lines of this particular 12.35m, 48-seat luxury coach that did its own thing among the slew of other stunning high-end machinery that lined the halls and walkways of the show.

Offset with a high-gloss black roof look that slides itself down onto the grille at the front and cheekily flicks itself up back at the tail, the cool blueish luminescence of the funky interior LEDs caught more than a few passing eyes and sucked us in like moths to a flame. And with our wings outstretched, ‘flipper-flappering’ at seemingly warp speed, Coach & Bus magazine floated on over to take a better look.

“The President range has been around for a number of years, but we changed its body-styling last June and we released it at the 2015 Melbourne show,” said Rodd Hood, joint director and owner of Bonluck’s Australian importer and distributor Bus & Coach Sales Australasia (BCSA), based in Yatala, Queensland.

“We painted it green to create attention and it certainly did that, and the response from that show onwards was very good. It’s been very exciting from a lot of operators, who were predominantly European vehicle buyers. My business partner, Athol McKinnon, and I went to visit a few European bus shows [earlier] and that’s probably what kicked off our our new [President] shape. We had a look at what the trends were with interior and exterior styling and that’s how we created the President 2,” he explained.

“It took Bonluck probably about 6 months only from once our ideas were all pulled together until the vehicle came off line, which is a very quick turnaround,” he added. “That’s the kind of speed and flexibility they offer us.”

According to Hood, BSCA has been dealing with Bonluck since 2008 – a boutique builder as opposed to a lot of other manufacturers who come from China, he says. Bonluck builds about 3000-4000 buses per year whereas, he says, others talk about doing 40,000 – 50,000.

“The good part of Bonluck is that they are very flexible in their builds for what they do for Australia. They actually sell off the back of what we do in Australia to other countries, too, because 70 per cent of Bonluck’s business is for export, so the balance is for their local market,” Hood explained.

“They do focus on high-end, high-quality vehicles out of their factory and with Australia probably having the most stringent design rules in the world, they use the Australian market to sell their other products to the UK, America, Dubai and a host of other countries.

“Even though we are relatively low volume for them, they use our expertise to help them take their products further. And that’s probably why we’ve got the edge on others, as well, because of their flexibility. The product that we actually get here in Australia is our product, it’s not their product imposed on us, which happens with other manufacturers,” he said.

Hood says it’s “our design chassis, it’s our design body” and that the Bonluck buses and coaches for this region are built to exactly how Australian customers choose, with the components they want.

“We are an Australian company; actually all we are doing is what we have done in the past - which was manufacture here in Australia - but now we are just manufacturing overseas because it’s a very labour intensive product, so the savings are in labour costs. The components we source are the same components, or very similar components, that a lot of the other major manufacturers use here in Australia, or that European chassis suppliers use in their own vehicles and we just have those fitted to our vehicles for Australia.”

The President is a very popular vehicle in BSCA’s model mix, says Hood, and more so now with the implementation in some Australian states of the increased axle weight to 18 tonne, which allows a vehicle like the President 2 to suit a lot more applications, whether it be a school bus, a charter bus, a day-tour bus, extended-touring vehicle because of the increased allowable carrying capacity.

?

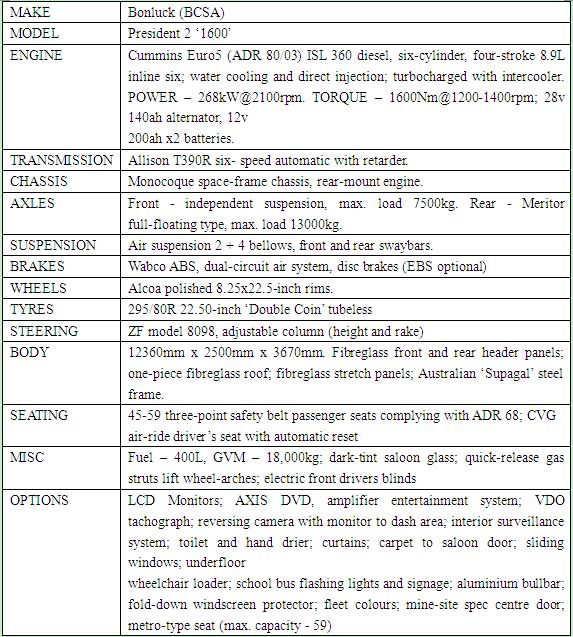

BUS SPECS

“This is also very cost effective in our case against spending another $70,000-80,000 more for a three-axle coach – as the only reason a majority of people are buying a three-axle coach is for additional carrying capacity axle-weight wise. So now you have two axles allowing us to do that.”

This allows the President to be used for a multitude of roles – even though BSCA offers other premium products like the Senator 12, which is its school charter bus based on the same chassis as the coach. The reason? A form of ‘standardisation’ in an operator’s fleet who might need to run both, so they are not having two [different] models of vehicle within the fleet. And a lot of those items are also passed onto the President 3 three-axle coach, as well, he says.

So what sets BSCA apart from other Australian distributors of ‘Chinese buses’? Hood is quick to point out: “We are the only importer in Australia that still uses Australian galvanised steel to build our vehicles overseas, for both chassis and body. Our steel comes from Australian tube mills in Brisbane, we send it to Bonluck in China and they assemble the bus. A lot of other people use steel from other countries in various shapes or sizes,and then we also still offer – as part of our model line-up - a stainless steel option if people require it, and that stainless steel comes form Bentler in Germany.”

Since last July BSCA has delivered more than 20 Presidents in various shapes and it recently landed its first 14.5m coach that’s going into charter-coach operation with a very high seating capacity, the company states. Aside from the 12.35m, 48-seat President 2 version pictured, there’s a 10.8m and a 13.2m President 2, as well.

“The Presidents are spread out all over the place, from inbound tour operators to TrainLink (Countrylink previously) in NSW like the V-Line in Melbourne, so we’ve got them operating on 7 days per week, 365 days a year services. It just goes into a multitude of different type operations. They could be out there doing mine work in WA, Qld, NT, Tasmania – we’ve got them in every state, so it’s a very multi-purpose type vehicle that can be easily changed to suit that particular client application,” Hood said.

New-design President 2 variants typically include: Australian ‘Super Gal’ galvanised steel chassis and body frame; 48 leather passenger seats plus driver; Cummins ISL 360 engine; Wabco EBS braking system; Thoreb Multiplex wiring system; Zinder wheelchair lift; a toilet; electric swing doors; separate driver’s air conditioning; wood-grain timber floor; multi-function steering wheel; electric pantograph bin doors; and a fully automated fire-suppression system.

“The Zinder wheelchair lift is a brand Bonluck uses,” Hood said. “It’s an upright, swing-out type wheelchair lift. The benefits of that over a cartridge lift is it uses less bin capacity and only had two micro switches on it, so from a maintenance point of view it’s a very simplistic-type wheelchair lift. It has a hydraulic over-ride, so if anything ever failed you still have a manual use. And obviously there again it’s very attractively priced for an operator.”

He added, “Our doors are manual top-hinge lift up doors, but we also do have an air-operated pantograph door option as well (fitted to the green bus). We are not forcing anyone to use what we might think might be right,” he explained. “The public is still indicting they like a choice of both so that’s what we offer.”

And with a philosophy to allow its customers to take its buses and coaches around any region to the preferred service centres of a customer’s choice – which BCSA will fully support (meaning they are not ‘forcing’ them to take a damaged or broken-down vehicle hundreds or thousands of kilometres away), the Bonluck brand in this region certainly has its following.

“We have a certain clientele that follow us and [they’re] obviously from past relationships, but there’s a lot of newer relationships as well, Hood explained. “There’s our ability to give the operator a vehicle with a massive amount of Australian input with high-quality components sourced from all around the world at, you can say, a very attractive and affordable price.” he said. “And that’s what sets us apart from some of our competitors.”